How Fiber Optic Conduit Protects Data Transmission and Network Integrity

Deploying fiber optic networks is about more than just choosing the right cable to meet your data transmission specs. When it comes to ease of installation and long-term network protection, the fiber optic conduit you choose is just as important as the cables inside.

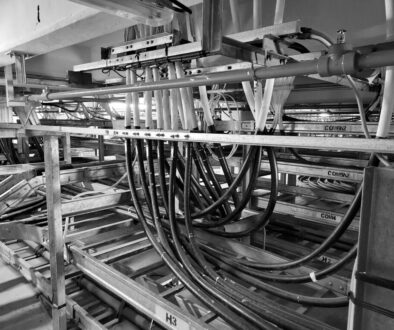

Achieving fiber optic network integrity means preventing damaged cables, severed connections, and related problems before they arise. It also means keeping cables accessible and well-organized to facilitate future network upgrades or expansion. So you need a conduit which has the flexibility to accommodate complex pathways, the durability to prevent external damage, and the stability to resist weathering and corrosion indefinitely.

That’s why Allwire typically recommends HDPE cable-in-conduit (CIC) for our customers’ fiber optic data transmission networks – optimized material properties in a cost-effective, pre-wired package that’s easy to install.

Fiber Optic Conduit: Essential to Long-Term Data Network Integrity

Facilitating Reliable Installation

Fiber optic cables are relatively fragile compared to many other materials, such as copper power conductors. They are sensitive especially at bends and where tension is applied during pulling. Conduit provides a rigid or semi-rigid path so that installers have a controlled route: bends are predictable, pulling tension can be managed (you can anchor and use pulling grips without snagging), and cable feed is smoother. That reduces the chance of micro-bends, crush damage, or breaking the fiber.

Pre-selecting conduit allows design engineers to specify minimum bend radii and maximum pulling tensions more reliably, since the path is known and fixed, rather than ad hoc. These standards help prevent signal attenuation caused by bends, stress, or uneven support. Consistency of path also simplifies testing and commissioning because you can better predict loss budgets.

Whether the fiber is run underground, through risers, alongside roadways, or in industrial settings, conduit gives a consistent means to traverse difficult zones. It allows pulling through manholes, cross-borings, under sidewalks, or building walls, while protecting the cable from sharp edges, compression, or abrasion.

Protecting Against Environmental Damage and Corrosion

Water is one of the biggest enemies of fiber cable integrity. Even fiber cables designed with water-blocking materials can suffer from condensation, flooding, or water migration over time. Proper conduit (sealed, continuous, with good joints and entry/exit fittings) prevents or greatly slows moisture ingress. This is especially important in underground or outdoor runs subject to groundwater or surface water infiltration.

HDPE conduit also protects against other major environmental threats to fiber optic networks:

- Soil movement and abrasion – Underground conduit protects cable jackets from rocks, shifting soil, and abrasive particles.

- UV exposure – Above-ground or exposed portions of fiber cable can degrade under ultraviolet (UV) light if not properly shielded; conduit provides a UV barrier.

- Fluctuating temperature extremes – Conduit helps buffer temperature swings, including heat absorbed by structures or cold-weather exposure. Proper materials accommodate thermal expansion and contraction while maintaining structural integrity.

Clean Cable Organization Streamlines Future Expansion

Conduit ensures fiber runs are accessible, predictable, and consistent. When it’s time to test, splice, pull replacements, or add new fibers, knowing where the conduit runs, having spare duct capacity, and maintaining clean entry and exit points saves labor and reduces the risk of damaging existing fibers.

Installing conduit with extra capacity—such as oversizing or installing multiple ducts—allows future fiber needs to be accommodated without tearing up infrastructure. A conduit that holds more fibers than initially required allows additional strands to be added later, while parallel conduits add redundancy or capacity without disrupting existing services.

Supporting Fiber Optic Network Rollouts with Reliable Conduit Solutions

At Allwire, our goal is to support fiber-optic deployment that delivers not just high initial performance, but long-term reliability and integrity. By applying best practices in material selection, installation techniques, and future-focused planning, network operators can ensure their fiber systems deliver secure, stable, high-bandwidth service for years to come.