Buried telecommunications cables and underground electrical infrastructure applications see some of the toughest conditions throughout the industry.

Buried telecommunications cables and underground electrical infrastructure applications see some of the toughest conditions throughout the industry. You have to contend with huge temperature fluctuations, wet conditions, shifting soil, to name a few of the biggest challenges… That’s why selecting the right conduit material is critical to facilitate easier installation in potentially challenging terrain, as well as to keep your cabling protected from future damage and corrosion.

At Allwire, we’ve found that high-density polyethylene (HDPE) electrical pipe and conduit has emerged as the best solution for most underground cabling projects. We’ve worked firsthand with utilities companies, contractors, and engineers across the country in the development of reliable HDPE underground conduit solutions which meet the unique needs of each project.

What Makes HDPE the Superior Choice for Underground Cabling?

Exceptional Durability and Strength

HDPE pipe and conduit offers excellent resistance to impact and external loads. It’s an ideal conduit option for underground installations where soil movement, vehicular loads, or nearby digging can pose threats. The material’s exceptional flexibility allows it to withstand such stress without cracking or breaking – qualities that traditional PVC conduit can’t always match.

Basically, HDPE’s flexibility and superior crack resistance make it ideal for the tough installation conditions of buried cable applications.

Outstanding Corrosion and Chemical Resistance

Beyond crushing, cracking, and mechanical damage, one of the major risks your underground conduit systems face is corrosion. Unlike metal pipes, which likewise offer exceptional strength, HDPE is inert to a wide range of chemicals and will not rust, rot, or corrode over time. This ensures that HDPE conduits provide long-term protection for cables in wet or chemically harsh environments.

Ease of Underground Installation

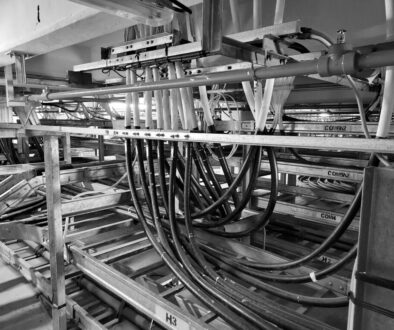

HDPE’s flexibility and light weight reduce the need for joints and fittings, minimizing installation time and labor costs. At Allwire, our cable-in-conduit systems arrive pre-installed with electrical cables, ready for direct burial or installation via directional boring or plowing. It’s a streamlined process that increases job-site efficiency and reduces handling risks.

Superior Joint Integrity with Heat Fusion

Unlike glued or threaded joints, HDPE conduit can be joined using heat fusion techniques, creating a seamless, watertight system. This eliminates the risk of infiltration by water or debris and enhances the long-term reliability of underground cable networks.

A Long, Reliable Service Life for Buried Cables

With a life expectancy measured in the decades, HDPE conduit is a long-term investment. When coupled with Allwire’s quality manufacturing and testing standards, our clients can plan out their installation project with confidence that their cabling is protected by the best pipe or conduit option available for the specific application at hand.

Allwire: Innovation and Experience in HDPE Conduit Solutions

More than just a cable and conduit supplier, Allwire is a partner in powering infrastructure. Backed by years of experience in the HDPE cable-in-conduit for underground installations, we deliver tailored solutions that meet the highest standards of performance and reliability.